Setting Xact Microarrayer for Microplate Printing.

In order to set the microarrayer for microplate printing it is necessary

to replace the Slide Holder with the Microplate Holder (LabNEXT p/n 110) and

change the software settings that describe geometry of the printing substrates.

Lab Next plate holder for Xact microarrayer accommodates two microtiter plates

so the number of substrates must be set to 2 substrates instead of 14 for slide

printing. The size of substrates must be also altered to the size of the

microtiter plates.

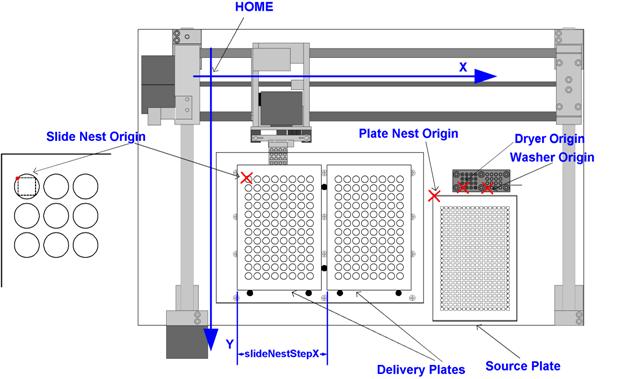

After setting parameters of the substrates it is necessary to specify

the new <Slide Nest Origin> and the spacing between the plates <slideNextStepX>. Other reference points on the

microarrayer work board (Plate Nest Origin, Dryer Origin, Washer Origin ) remain the same.

After performing the actions described above it will be possible to

specify print jobs using the Job Wizard program.

Register

a new configuration of the microarrayer.

-

Run ConfigureSystem program.

-

- Click [Edit] button next to the <spotter> title in the “LabNext

Equipment Configurator” dialog.

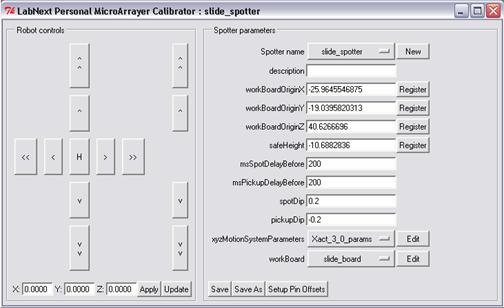

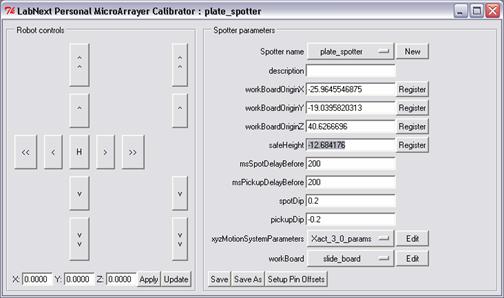

- In the opened “LabNext Personal Microarrayer Calibrator” dialog click

on the [Save As] button.

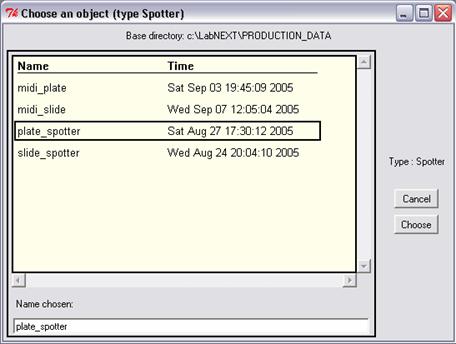

- In the opened dialog “Choose an object (type Spotter)” type in the

<Name chosen> field type: plate_spotter and press [Choose] button in the right side of

the dialog window.

-Close the “LabNext Personal Microarrayer Calibrator” dialog window

- Get back to already opened “LabNext Equipment Configurator”

dialog and click on the button next to the <spotter> string. In the

opened drop-down list select <plate_spotter>

entry.

- Press [Save] button in the low left corner of the “LabNext Equipment Configurator” dialog window.

- Click [Edit] button next to the <spotter> title in the “LabNext

Equipment Configurator” dialog. This will open

‘LabNext Personal Microarrayer Calibrator” dialog. Please check if the the opened dialog refered to the plate_spotter.

(<Spotter Name> string in the right panel should indicate plate_spotter).

-

Insert a pin into the far-left hole of the print head.

x o o o

o o o o

o o o o

- Install Microplates in the

plate holders.

- Press [H] button in the

center of the “Robot Controls” panel. Wait till robot performs homing

operation.

- Using arrow buttons at the

“Robot Controls” panel move the tip of the pin 1-2mm over the highest object on

the work board and click on the [Register] button next to the <safeHight> string at the “Spotter parameters” panel.

- Press [Save] button in the

bottom of the “LabNext Personal Microarrayer Calibrator” window.

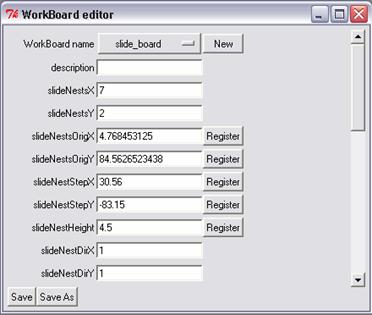

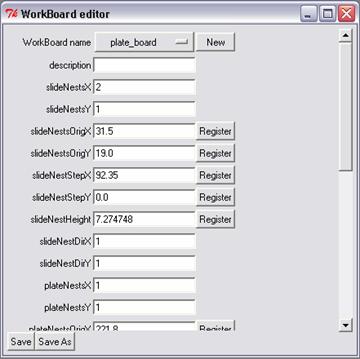

- Press [Edit] button next to <workBoard>

string in the right panel “Spotter parameters”. This will open the “WorkBoard Editor” window.

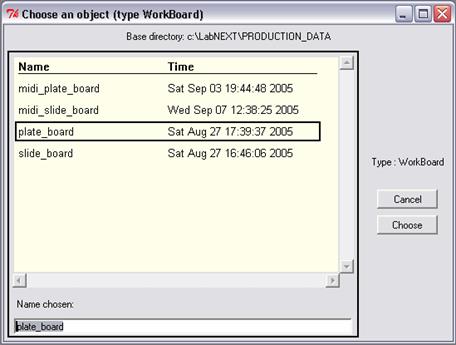

- In the “Work Board editor” window press [Save As] button.

- In the opened “Chose an Object (type WorkBoard)”

dialog type plate_board in the <Name Chosen> field.

- Click on the [Choose] button in the left part of the dialog window.

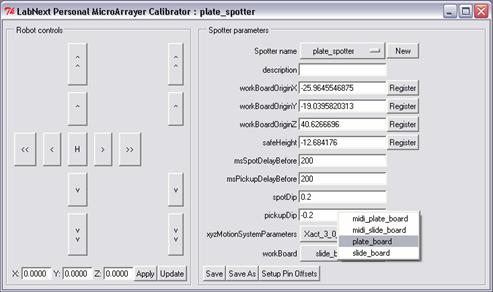

- Return to the opened “LabNext Personal Microarrayer Calibrator”

window.

- Click on the button next to the <workBoard>

string. From the drop-down list select the plate_board entry.

- Click on the [Save] button at the bottom part of the “LabNext Personal

Microarrayer Calibrator” window.

- Press [Edit] button next to <workBoard>

string in the right panel “Spotter parameters”. This will open the “WorkBoard Editor” window.

- Please ensure that plate_board is

indicated on the button next to <WorkBoard

name> string at the very top of the “Work Board editor” window.

- Set <slideNestsX> = 2

- Set <slideNestsY> = 1

- Set <slideNestStepX> = 92.35

- Set <slideNestStepY> = 0

NOTE: slideNestStepX = 92.35 mm for plate holders manufactured by

LabNEXT. In case of using self made holders please take a measurement in

millimeters of the distance between the left edges of the microplates and use

this measurement as a value for <slideNestStep>

variable.

- Using manual controls move the pin to the upper-left corner of the

upper-left well of the left microplate

- Press [Register] next to <slideNestOriginX>

string

- Press [Register] next to <slideNestOriginY>

string

- Remove the microplate from the holder and using the manual controls

touch with the tip of the pin surface of the plate holder.

- Press [Register] next to <slideNestHeight>

string

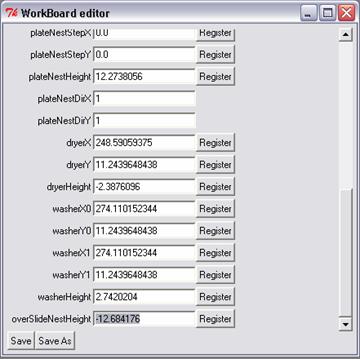

- Scroll to the bottom part of the “WorkBoard

editor” window.

- Using robot manual controls move the pin tip 1-2 mm over the delivery

plates.

- Press [Register] next to <overSlideNestHeight>

string

- Click on the [Save] button at the bottom of the “WorkBoard

editor” dialog.

- Close the “WorkBoard editor” dialog window.

- Please ensure that plate_spotter is

indicated under the current configuration

at the “LabNext Equipment Configurator”

- Close “LabNext Equipment Configurator”

dialog window.

This ends the setting of the system configuration for microplate

printing. After that configurations can be toggled between plate and slide

printing just by changing the <spotter> parameter.

Setting

Substrate Parameters and Creating a Print Job for Printing in a 96-well Microplate.

- Start JobWizard.

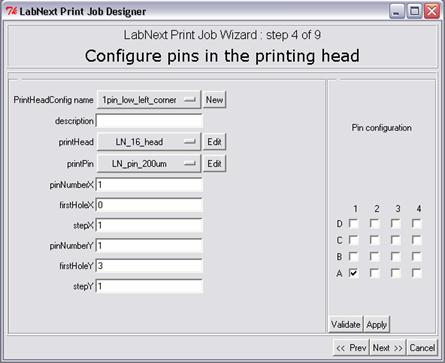

- At the Step 4 “Configure Pins in the Printing Head” please ensure that

configuration used for printing with one pin.

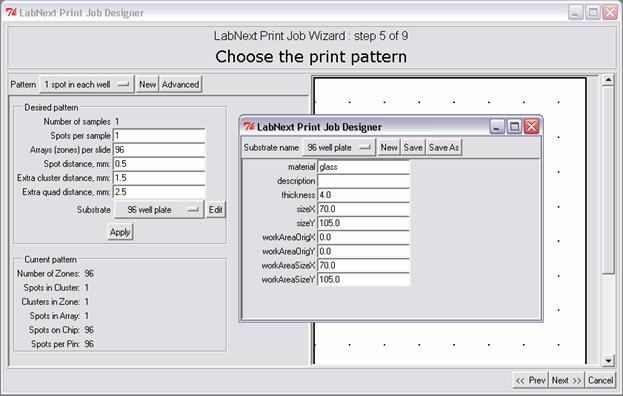

- At the Step 5 “Choose the print pattern” click

on the button next to <Substrate> string.

- In the opened dialog “Substrate Name” click at the [New] button and

register a new substrate with the “96 well plate” name.

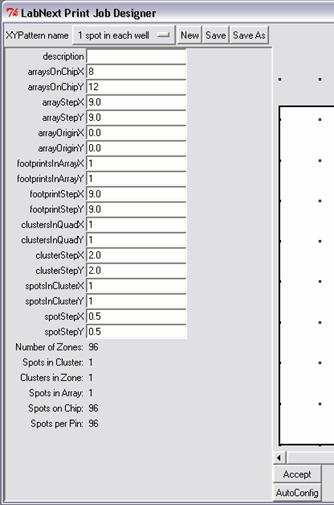

- Enter parameters of the plate as shown at the screenshot below.

-

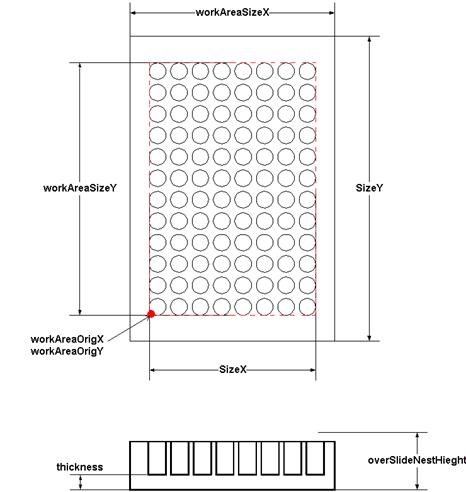

Parameters entered above correspond to the standard

96-well microplates. In case of using non standard plates take the measurements

as shown on the drawing below and use them for the settings.

Setting

Sample Print Pattern

The sample print pattern specifies printing one spot in each well of the

96-well plate. CLUSTER in the sample

pattern contains only one spot <spotsInClusterX> = 1 and

<spotsInClusterY> =1. More complex patterns can be derived from the

sample pattern by changing parameters in the CLUSTER the same way it is done

for printing microarrays on glass substrates.

- At the Step 5 “Choose the print pattern” click on the [Advanced]

button.

- Set <arraysOnChipX> = 8 <arraysOnChipY> = 12. This

corresponds to 96 wells. In each well the spotter will form identical array.

- Set <arrayStepX> = 9 and <arrayStepY> = 9. Those settings

correspond to the spacing between wells of 96-well plates.

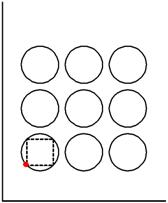

- Set <arrayOriginX>=0 and <arrayOriginY>=0. The spot with

these settings will be printed in the corner of a quad inserted in the round

well as show at the picture below.

Making values of the <arrayOriginX> and <arrayOriginY>

positive will move the point towards center of the well to the left and higher

correspondingly.

- FOOTPRINT and QUAD parameters are irrelevant since the printing is

done with one pin.

- Save the sample pattern under the name of 1 spot in each well

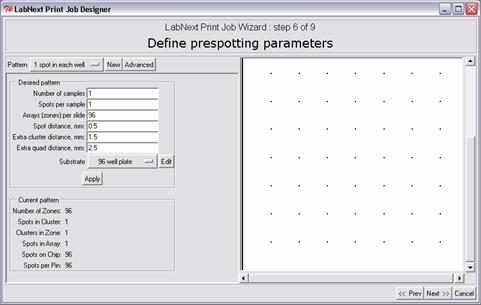

- At the Step 6 “Define prespotting parameters” choose the same pattern

as for printing 1 spot in each well and

the same substrate 96 well plate

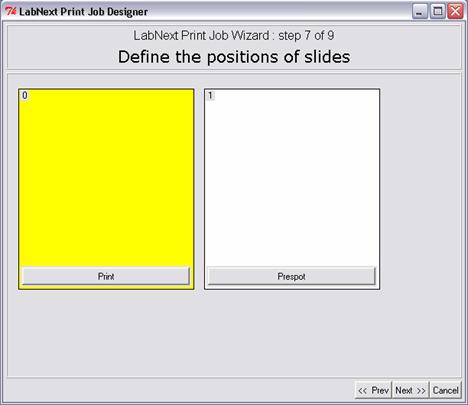

- At the Step 7 “Define the position of the slides” two substartes must be displayed on the print board. Choose one

for prespotting and one for printing. Typically LabNEXT pins don’t require more

than 1-2 prespotting hits. The “prespotting” plate therefore can be used for

real printing.