Application Manual for STS Microarray Pins

We frequently update this manual based on ongoing testing and use of the pins in our lab and customer feedback. Detailed pins specifications and pricing can be obtained at www.labnext.com/sts.htmlPrecautions

All parts of the STS pins are made of stainless steel. Tips are rated for hardness - Rockwell scale C36. STS pins withstand most of organic solvents but may corrode in acids or alkali solutions. 400um pin tips can be easily bent if lateral force is applied.Operations

Solid pins pick-up a droplet of liquid enough for only one spot. They should be refilled after each deposition. Use "refill" function in the Xact and THOMAS software. BOOscara and BOOcartesian arrayers define refill as a dedicated "group" in the spotting pattern. We recommend less than 1mm submerge depth for picking up samples from microplate wells. Ideally submerge depth should be as small as possible because liquid sticks to the side of the pin tips as wall as to the contact area at the tip's end. There are no specific recommendations on the vertical speed for pick-up and deposition. The pins were tested with a wide range of vertical speed settings and produced similar results.Array printed with 400um STS pin. Spot distance 1 mm.

Array printed with 1500um STS pin. Spot distance 3 mm.

Cleaning

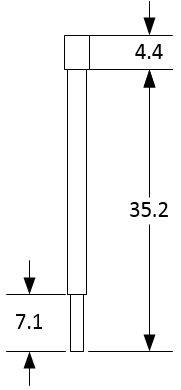

Cleaning during operations is done in the arrayer washing/drying station which consists of washing liquid reservoir and vacuum dryer. For cleaning use solutions that dissolve printed compounds and the buffer. Cleaning outside of the arrayer can be done with any organic solvent such as acetone, alcohol or DMSO. You can accurately touch the tips of STS pins and wipe them with tissue. Avoid applying significant lateral force to the tip.Dimensions Reference for STS Microarray Pins.